Introduction

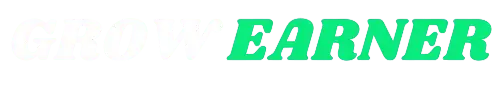

In 2025, Global Supply Chain Disruptions continue to pose significant challenges for economies worldwide, particularly in the United States. These disruptions have led to increased costs, product shortages, and significant delays in the availability of essential goods. Consumers in the U.S. are feeling the effects directly in their daily lives, whether through rising prices, difficulty finding specific products, or longer waiting times for deliveries.

The COVID-19 pandemic, geopolitical tensions, labor shortages, and climate-related disasters have all contributed to Global Supply Chain Disruptions, making it difficult for businesses to maintain stable inventory levels and pricing structures. As a result, U.S. consumers are facing an unpredictable market with fewer choices and higher costs.

This article explores the root causes of Global Supply Chain Disruptions, their impact on U.S. consumers, how businesses and individuals are adapting, and what the future holds for the global supply chain in 2025.

Causes of Global Supply Chain Disruptions in 2025

1. Lingering Effects of the COVID-19 Pandemic

While the world has largely moved past the immediate health crisis of COVID-19, its economic impact remains. Many manufacturing hubs, especially in China, India, and Southeast Asia, are still struggling with workforce shortages and production backlogs. These delays trickle down to the U.S. market, causing continued Global Supply Chain Disruptions that affect industries ranging from electronics to pharmaceuticals.

2. Geopolitical Tensions and Trade Restrictions

Trade relations between major economic powers, particularly the U.S. and China, remain tense. Tariffs, sanctions, and political conflicts have created bottlenecks in global trade, affecting everything from semiconductors to automobile parts. The ongoing conflict between Russia and Ukraine has also disrupted global energy supplies, leading to fuel price hikes that increase shipping costs, further contributing to Global Supply Chain Disruptions.

3. Labor Shortages and Rising Operational Costs

Many industries are facing a severe workforce shortage, making it difficult to maintain efficient production and logistics operations. In the U.S., the trucking industry, which plays a crucial role in supply chain logistics, is experiencing a shortage of drivers. This issue is compounded by increasing wages and higher operational costs, making it more expensive for companies to transport goods across the country.

4. Climate Change and Natural Disasters

Extreme weather events, including hurricanes, wildfires, and floods, have significantly impacted global supply chains. Ports, warehouses, and transportation networks have been damaged or shut down due to natural disasters, delaying shipments and increasing costs. For example, in 2024, severe storms in key manufacturing regions caused factory shutdowns, adding another layer to the ongoing Global Supply Chain Disruptions in 2025.

Impact of Global Supply Chain Disruptions on U.S. Consumers

1. Rising Prices and Inflation

One of the most visible effects of Global Supply Chain Disruptions is rising inflation. Due to higher production and transportation costs, businesses are forced to pass these expenses onto consumers. As a result, essential goods such as groceries, household products, and clothing have become more expensive.

Industries particularly affected include:

- Automobiles: New and used car prices have surged due to semiconductor shortages and limited production.

- Electronics: Laptops, smartphones, and gaming consoles are in short supply, leading to higher costs.

- Food & Beverages: Delays in agricultural imports and rising fuel prices have driven up food costs in grocery stores.

For U.S. households already struggling with inflation, these increased costs make it more challenging to manage daily expenses.

2. Product Shortages & Delayed Deliveries

Retailers are finding it difficult to maintain stock levels due to Global Supply Chain Disruptions. Many consumers have noticed frequent “out of stock” labels when shopping online or in stores. Items that used to be readily available now require pre-orders or long waiting periods.

For example:

- Holiday shopping in 2024 saw record-high delays, with many customers receiving their gifts weeks after Christmas.

- Grocery stores have had difficulty keeping fresh produce, dairy, and meat products in stock due to transportation issues.

- Home improvement supplies, such as lumber and appliances, remain backlogged due to manufacturing delays.

These shortages not only cause inconvenience but also force consumers to seek alternative, often more expensive, options.

3. Increased Cost of Living

The combination of rising product prices, higher transportation costs, and inflation has significantly increased the cost of living in the U.S. Gasoline prices remain high due to global energy supply disruptions, leading to increased commuting and shipping costs.

Housing materials and rental prices have also surged because of supply chain struggles in the construction industry. For many families, the added financial burden means having to make difficult choices about their spending priorities.

4. Limited Choices & Reduced Product Quality

With manufacturers struggling to keep up with demand, some companies have resorted to cost-cutting measures. This means fewer product varieties on store shelves and, in some cases, lower quality goods.

For instance:

- Popular food brands have reduced package sizes while keeping prices the same (a phenomenon known as “shrinkflation”).

- Clothing brands have opted for lower-quality fabrics due to raw material shortages.

- Electronics manufacturers have replaced premium components with lower-quality alternatives to maintain production levels.

Consumers are left with fewer options and must compromise on quality or pay a premium for high-quality products.

How Businesses & Consumers Are Adapting

1. U.S. Companies’ Response

To combat Global Supply Chain Disruptions, many U.S. businesses have started reshoring and onshoring production. By manufacturing goods domestically, companies aim to reduce dependency on foreign suppliers and mitigate risks associated with international shipping delays.

Additionally, businesses are investing in:

- Automation & AI: To reduce reliance on human labor, companies are integrating AI-driven supply chain management.

- Diversified Sourcing: Instead of relying on a single supplier, companies are partnering with multiple global manufacturers to minimize risks.

2. Consumer Strategies to Cope

U.S. consumers are also adjusting their shopping habits in response to Global Supply Chain Disruptions:

- Buying Local: Many consumers are turning to local businesses and farmers’ markets to reduce dependency on imported goods.

- Bulk Purchasing: Households are stocking up on non-perishable items to avoid future price hikes.

- Alternative Brands: Instead of sticking to well-known brands, consumers are exploring budget-friendly alternatives.

By adopting these strategies, consumers can better navigate the uncertainties of the current supply chain crisis.

Future Outlook: Will Global Supply Chain Disruptions Improve in 2025?

Experts predict that while some improvements may be seen in late 2025, Global Supply Chain Disruptions will remain a challenge for the foreseeable future. Governments and industries are working on long-term solutions, such as expanding domestic manufacturing and enhancing logistics infrastructure, but these efforts take time to implement.

Potential solutions include:

- Improved U.S. Trade Policies: Easing trade restrictions could help stabilize supply chains.

- Investment in Sustainable Supply Chains: Eco-friendly and resilient supply chain models could prevent future disruptions.

- Technology-Driven Efficiency: AI and blockchain technology will play a key role in making supply chains more transparent and efficient.

While the situation may gradually stabilize, U.S. consumers should continue to expect some level of unpredictability in product availability and pricing throughout 2025.

Conclusion

Global Supply Chain Disruptions have significantly impacted U.S. consumers, affecting everything from prices and product availability to overall cost of living. While businesses and consumers are finding ways to adapt, the reality is that these challenges will persist for some time.

By understanding the root causes of supply chain disruptions and adjusting shopping habits accordingly, consumers can navigate these uncertain times more effectively. Staying informed about market trends and planning purchases strategically can help mitigate the impact of supply chain issues on everyday life.

As the world continues to adapt, the hope is that innovative solutions and policy changes will lead to a more resilient and efficient global supply chain in the years to come Read more

FAQs

<h5>1. What Are Global Supply Chain Disruptions, and Why Are They Important in 2025?</h5>

Global Supply Chain Disruptions refer to delays, shortages, and inefficiencies in the movement of goods and services across international and domestic markets. These disruptions impact everything from manufacturing and shipping to retail availability and consumer prices.

In 2025, Global Supply Chain Disruptions continue to affect U.S. businesses and consumers due to factors such as geopolitical conflicts, climate-related disasters, and ongoing labor shortages. When supply chains are unstable, industries struggle to maintain production, leading to higher costs and limited product availability. Understanding these disruptions is essential for businesses and consumers to make informed purchasing and investment decisions.

<h5>2. What Are the Main Causes of Global Supply Chain Disruptions in 2025?</h5>

Several factors contribute to Global Supply Chain Disruptions in 2025, including:

- Geopolitical Tensions: Trade conflicts between the U.S. and China, the Russia-Ukraine war, and economic sanctions have disrupted international shipping and sourcing.

- Labor Shortages: Truck driver shortages in the U.S., factory worker deficits in Asia, and strikes in key industries have slowed production and deliveries.

- Climate Change & Natural Disasters: Hurricanes, floods, and wildfires have damaged critical infrastructure, leading to delays in shipping and production.

- Shipping & Logistics Bottlenecks: Congestion at major U.S. ports, high fuel costs, and limited cargo availability have driven up transportation expenses.

These combined factors make it challenging for businesses to maintain stable supply chains, directly affecting consumers.

<h5>3. How Do Global Supply Chain Disruptions Affect Prices in the U.S.?</h5>

One of the biggest consequences of Global Supply Chain Disruptions is rising prices for everyday goods and services. When supply chains break down, the cost of raw materials, transportation, and labor increases, leading to price hikes across multiple industries.

For example:

- Food & Grocery Prices: Delays in agricultural imports and higher fuel costs increase the price of fresh produce, dairy, and packaged goods.

- Automobiles & Electronics: Semiconductor shortages lead to limited production, driving up the cost of cars, smartphones, and laptops.

- Housing & Construction: Supply chain delays in materials like lumber and steel result in higher home-building and renovation costs.

These price increases contribute to inflation, reducing consumer purchasing power and making everyday life more expensive.

<h5>4. How Do Global Supply Chain Disruptions Impact Small Businesses in the U.S.?</h5>

Small businesses are among the hardest hit by Global Supply Chain Disruptions because they often lack the resources and supplier networks of larger corporations. Delays in receiving raw materials or inventory can lead to lost sales, customer dissatisfaction, and financial strain.

Many small businesses in the U.S. have had to:

- Increase prices to offset higher supply costs.

- Seek alternative suppliers, sometimes sacrificing quality or consistency.

- Reduce product offerings due to unavailable materials.

While some businesses are adopting strategies like local sourcing and automation to mitigate these issues, supply chain instability remains a significant challenge.

<h5>5. Are Online Retailers Also Affected by Global Supply Chain Disruptions?</h5>

Yes, online retailers face major setbacks due to Global Supply Chain Disruptions. E-commerce giants like Amazon, Walmart, and Shopify-based businesses rely on a steady inflow of goods to fulfill customer orders. When supply chains slow down, these retailers experience:

- Longer Delivery Times: Consumers face extended shipping delays, especially for imported goods.

- Out-of-Stock Items: Popular products may be unavailable for weeks or months.

- Higher Shipping Costs: Increased fuel prices and logistic challenges make it more expensive to transport goods.

These disruptions frustrate customers, leading to increased competition among retailers to secure inventory and maintain reliability.

<h5>6. How Are U.S. Companies Adapting to Global Supply Chain Disruptions?</h5>

To combat Global Supply Chain Disruptions, many U.S. companies are shifting their strategies, including:

- Onshoring & Nearshoring: Moving production back to the U.S. or neighboring countries like Mexico to reduce dependency on foreign suppliers.

- Diversifying Suppliers: Businesses are sourcing materials from multiple countries to minimize risk.

- Investing in Technology: AI-driven logistics and blockchain tracking systems help companies improve supply chain visibility and efficiency.

- Stockpiling Inventory: Some businesses are keeping larger inventories to avoid stockouts during supply chain delays.

These adaptations aim to create more resilient supply chains, though challenges remain in fully overcoming disruptions.

<h5>7. What Role Do Ports and Shipping Delays Play in Global Supply Chain Disruptions?</h5>

Ports are critical hubs in the supply chain, and delays at major U.S. ports like Los Angeles, Long Beach, and New York have exacerbated Global Supply Chain Disruptions. Key issues include:

- Congestion: Ships wait for days or weeks to unload cargo due to labor shortages and inefficient port operations.

- Container Shortages: Limited availability of shipping containers disrupts global trade flows.

- Increased Shipping Costs: Rising fuel prices and longer transit times make shipping more expensive.

These bottlenecks slow down the movement of goods, leading to stock shortages and higher costs for businesses and consumers alike.

<h5>8. How Can U.S. Consumers Adapt to Global Supply Chain Disruptions?</h5>

Consumers can take proactive steps to mitigate the impact of Global Supply Chain Disruptions on their daily lives, such as:

- Planning Purchases in Advance: Buying essential items early to avoid stock shortages.

- Exploring Local Alternatives: Supporting local businesses and farmers to reduce dependency on imported goods.

- Being Flexible with Brands & Products: Opting for alternative brands or generic products when preferred options are unavailable.

- Bulk Buying Non-Perishables: Stocking up on staple items that might see price increases in the future.

By adjusting shopping habits, consumers can navigate the ongoing supply chain challenges more effectively.

<h5>9. Will Global Supply Chain Disruptions Continue for the Rest of 2025?</h5>

Experts predict that Global Supply Chain Disruptions will persist throughout most of 2025, though some improvements may be seen by late in the year. Factors influencing the timeline include:

- Government Policy Changes: Trade agreements and supply chain incentives could help ease disruptions.

- Technological Advancements: AI-driven logistics and automation may speed up production and shipping processes.

- Global Economic Stability: If inflation stabilizes and geopolitical tensions ease, supply chains may gradually recover.

While improvements are expected, consumers and businesses should continue preparing for intermittent supply chain challenges.

<h5>10. What Long-Term Changes Can Prevent Future Global Supply Chain Disruptions?</h5>

To prevent future Global Supply Chain Disruptions, businesses and governments are focusing on:

- Strengthening Domestic Manufacturing: Increasing U.S. production capacity to reduce reliance on overseas suppliers.

- Improving Logistics Infrastructure: Investing in port expansions, railway systems, and trucking efficiency.

- Enhancing Supply Chain Transparency: Using AI, IoT, and blockchain technology to improve tracking and risk management.

- Sustainable & Green Supply Chains: Encouraging eco-friendly production and transportation methods to mitigate climate-related disruptions.

Leave a Reply